Precision Mold Machining Solutions for Diverse Industries

Table of Contents

Advanced Mold Machining Applications and Case Studies #

Vision Wide offers a wide range of high-precision machining solutions tailored for mold manufacturing across various industries. Below is an organized showcase of real-world applications, highlighting the machining processes, materials, and results achieved with our technology.

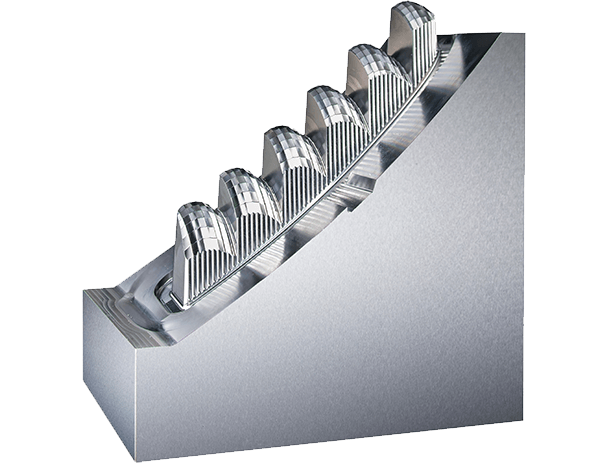

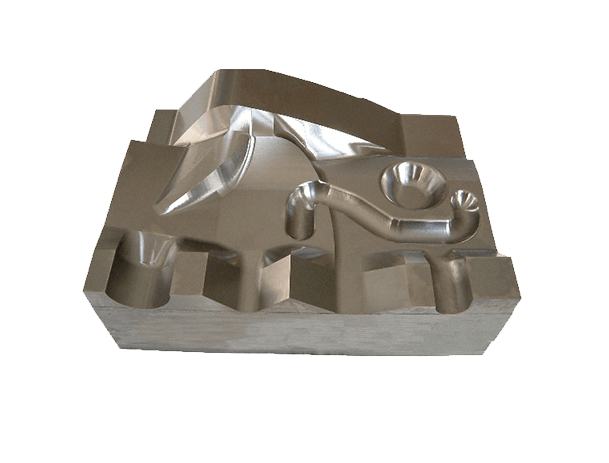

Automobile Light Mold #

- Model: ASM

- Material: 2311 Die steel

- Size: L360 x W160 x H360mm

- Linear project cutting with multiple inclined planes and oblique angle cutting to enhance machining efficiency.

- Surface roughness: Ra 0.4µm

- Contour accuracy: 0.04mm

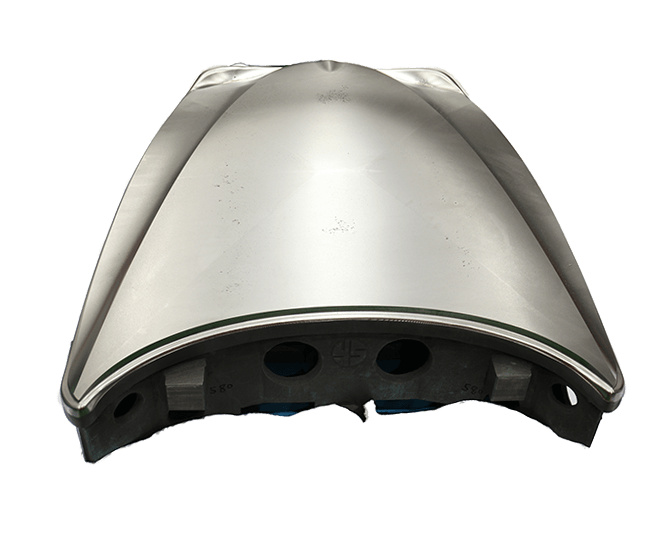

Headlight Mold #

- Model: SE / GS / GSF

- Material: P20 Die Steel

- Size: L800 x W550 x H250mm

- 0.2G high acceleration mold finishing.

- D25 high feed rough machining: F10,000 mm/min.

- D10R5 high speed surface finish: S12,000 rpm, F4,000 mm/min.

- Surface roughness: Ra 0.4μm

- Contour accuracy: 0.04 mm

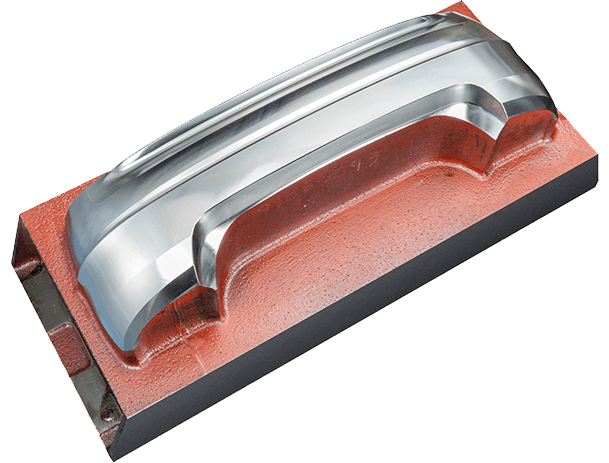

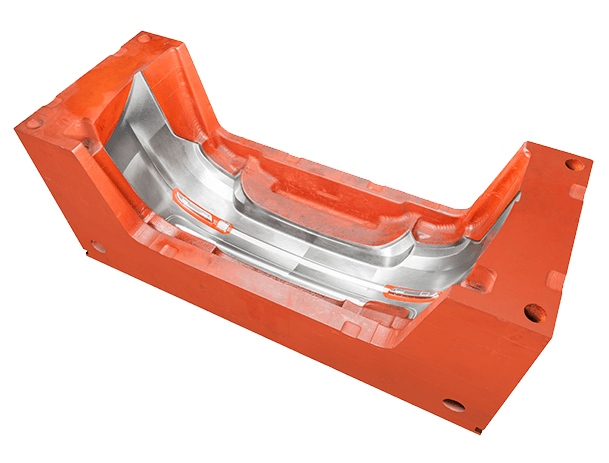

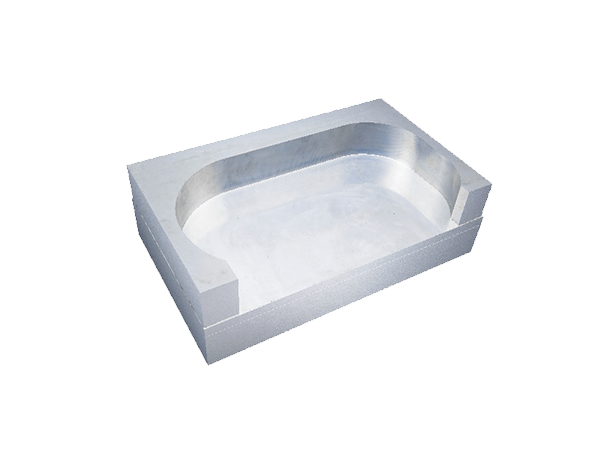

Bumper Mold #

- Model: SF

- Material: FC300

- Size: L1,000 x W400 x H350mm

- Long spindle nose enhances tool rigidity and reduces cutting vibration.

- D20R10 ball end tool reciprocating projection machining, pitch 0.5mm.

- Spindle speed: 12,000 rpm

- Feed rate: 5,000 mm/min

Automotive Reflector Light Core #

- Model: SE/GS series

- Material: NAK80 die steel

- Size: 160 x 160 x 100 mm

- Surface roughness: Ra 0.4μm

- Contour accuracy: 0.02 mm

- D3R1.5 ball end machining

- Spindle speed: 12,000 rpm

- Feed rate: 1,500 mm/min

Headlight Cavity Finishing #

- Material: Alloy steel

- Size: L151mm x W105mm x H155mm

- Surface height difference: 103mm

- Surface roughness: Ra 0.8 mm

- Long tool machining (tool length 262mm)

- Tool: D12R6 Hard ball end

- Tool path: Zig-zag contour processing

- Spindle speed: 8,000 rpm

- Feed rate: 2,000mm/min

- Total machining time: 1hr 58min

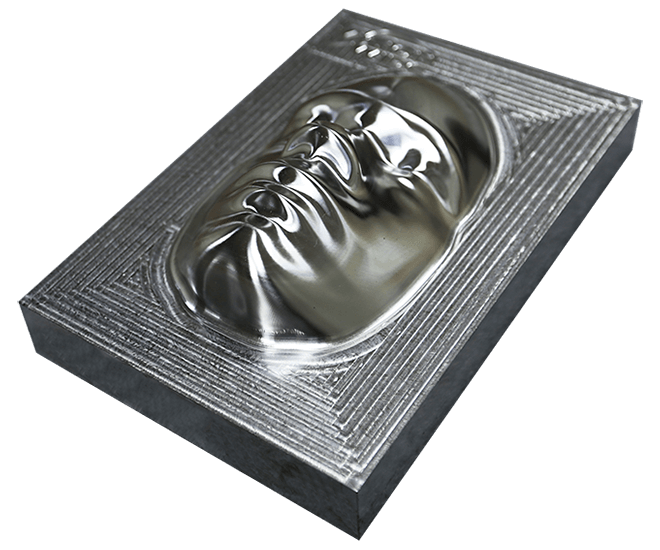

Mask Core Mold #

- Model: F series

- Material: S45C

- Size: 300 x 200 x 100 mm

- High speed and high accuracy mold machining

- High contour accuracy: 98.5% point error < 0.02mm, 85.8% point error < 0.012mm

- D12R6 ball end tool, 45° project zig-zag cutting

- Spindle speed: 10,000 rpm

- Feed rate: 4,000 mm/min

Benz Mold #

- Material: NAK 80 die steel

- 0.2G high acceleration mold machining

- High federate rough machining: D25, F10,000mm/min

- High speed surface finish machining: F4,000mm/min

- Surface roughness: Ra 0.4μm

- 45° project zig-zag cutting

- Spindle speed: 12,000 rpm

- Feed rate: 4,000 mm/min

Bumper Mold (Large) #

- Model: FA

- Material: FC300

- Size: 900 x 2300 x 930mm

- 5-axis synchronized machining, 30% efficiency improvement

- Long spindle nose for enhanced rigidity and reduced vibration

- D20R10 ball end tool, project zig-zag cutting

- Spindle speed: 8,000 rpm

- Feed rate: 5,000 mm/min

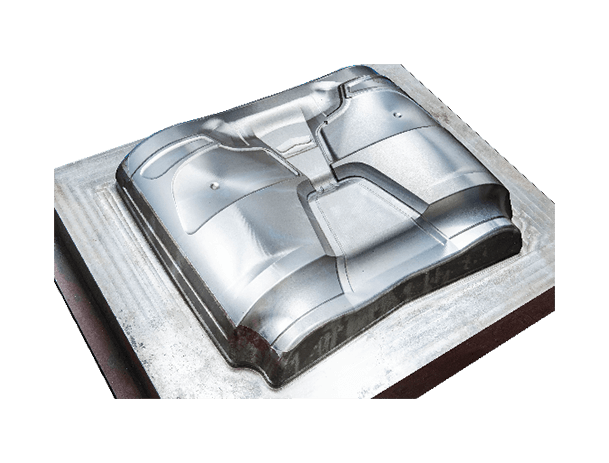

Automotive Sheet Metal Mold #

- Model: FA

- Material: FC300

- Size: 2300 x 1600 x 250mm

- 0.2G high acceleration mold machining

- High feedrate die surface finishing: F7,000mm/min

- High clear machining path

- Total finish time: 6.3hr

- D25 ball end tool, 45° project zig-zag cutting

- Spindle speed: 8,000 rpm

- Feed rate: 7,000 mm/min

Engine Hood Mold #

- Material: FC300

- Size: 2,000 x 1,600 x 500mm

- 10 m/min high speed machining

- 0.3G high acceleration machining

- Total finish time: 5.2 hrs.

- D25 ball end tool, pitch 0.5mm, surrounding isometric machining

- Spindle speed: 12,000rpm

- Feed rate: 5,000 mm/min

Mold Verification Workpiece #

- Model: GS/ SE

- Material: 2311

- Size: 150 x 60 x 30 mm

- D4R2 ball end tool finish

- Surround interpolation milling without tool mark

- Precise Z-reversed cutting with sharp edges and corners

- Surface roughness: Ra 0.8µm

Car Stamping Mold #

- Material: P20

- Size: L640mm x W505mm x H270mm

- Finish Tool: D16R8 Ball End, finish pitch 0.3mm

- Tool Path: 45° project zig-zag cutting

- High feed rate finishing: F3000→F5000

- High acceleration cutting: 0.05G→0.2G

- Total finishing time reduced by 20%: 6hr08min→4hr54min

- Surface roughness: Ra 0.6μm

- Spindle Speed: 15,000 rpm

- Feed rate: 5,000mm/min

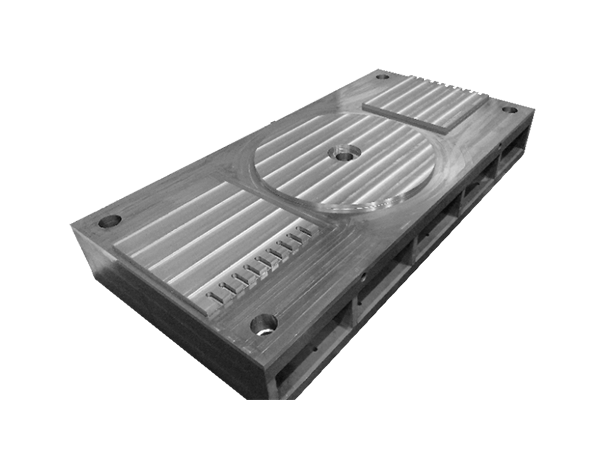

Mold Base High Feedrate Machining #

- Model: SE / GS

- Material: S45C

- Size: 800 x 500 x 250mm

- Vc 220 m/min, 10 m/min high federate machining

- Boring positioning accuracy: 0.006 mm (Pitch 400x700mm)

- Spindle speed: 2,000rpm

- D40 R1 high feed tool

High Positioning Inspection Workpiece #

- Model: F Series/ BM/ XM/ XML/ XMF

- Material: FC30

- Size: 2,000 x 1,000 x 200mm

- 1.8x0.8 m high position accuracy of boring hole: 0.02mm

- D900 circular interpolation machining, circularity: 0.02mm

- 400x400mm squareness: 0.01mm

24m High Speed Machining Workpiece #

- Material: Al6061

- 24 m high speed machining, equal TEA tool path

- 70 mm long tool machining

- Tool: D25R1 end mill

- Spindle speed: 10,500rpm

- Feed rate: 24,000 mm/min

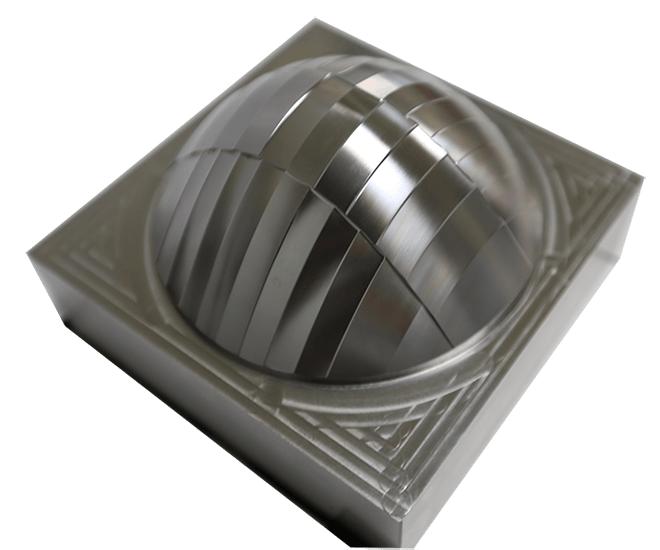

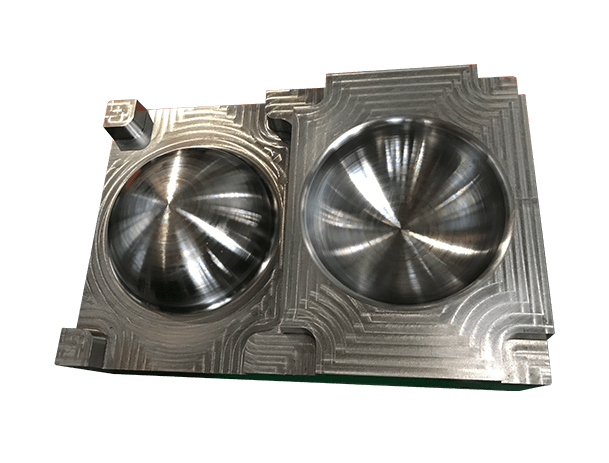

Ball Mold #

- Model: GS/ SE

- Material: 2311 Die steel

- Size: 300 x 200 x 150 mm

- D12R6 ball end tool, circular interpolation milling without tool mark

- Surface roughness: Ra 0.4µm

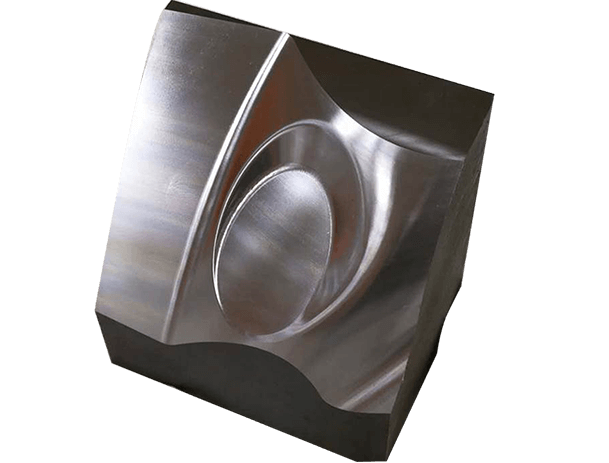

Deep Cavity Mold #

- Model: SM

- Material: P20 die steel

- Short-distance surround machining, high-precision feed control

- Four-quadrant commutation without chatter marks

- Simultaneous machining to maintain high finish, no over-cutting, no chatter marks

- Plane accuracy: -0.011 ~ 0.006mm

- Spherical accuracy: -0.012 ~ 0.006mm

- D20R1 end mill finishing

- Spindle speed: 3,500rpm

- Feed rate: 5,200mm/min

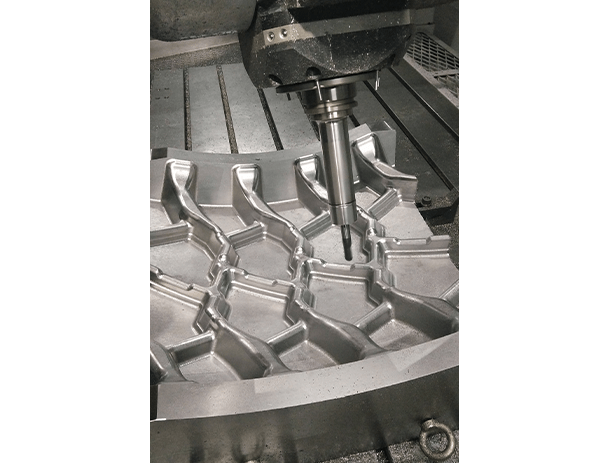

TIRE Mold (Segment Type) #

- Model: FA

- Material: S45C

- Size: 660 x 600 x 260mm

- Corner smooth flow cut via 5-axis synchronized machining

- D25 high feed rough cutting: F10,000

- F3,000 R6 finishing

- Multi-axis project machining

- Spindle speed: 15,000 rpm

- Feed rate: 4,000 mm/min

Ball Shape #

- Model: FA / GSF

- Material: Al6061

- Size: D280 mm

- 5 axis synchronized machining without deceleration

- High synchronized feedrate: F2,000

- High servo control, each axis feed > F10,000mm/min

- Finishing Time: <20min

- Surface accuracy: <±0.02mm

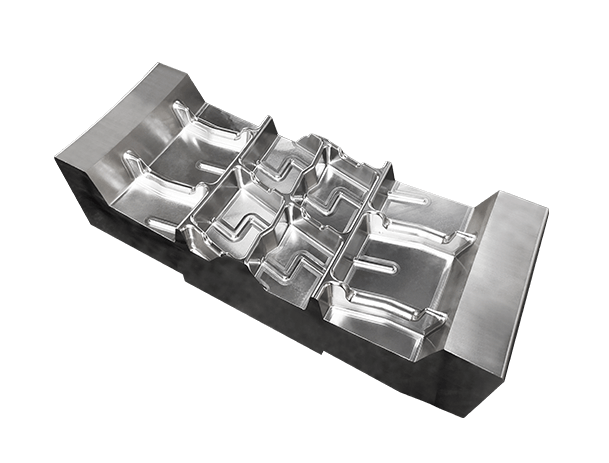

Tire Mold (Segment type) #

- Material: P20 Die Steel

- Size: L310 x W131 x H95mm

- One-step machining: High-feed rough machining, high-speed mold machining, and 5-axis synchronized machining corner flow cut

- High-feed rough machining: F7,200mm/min, Ap0.6mm

- High-speed mold machining: Ra<0.5μm

- 5-axis synchronized R0.5mm machining, effectively reducing tool length and avoiding interference.

There are no articles to list here yet.