Comprehensive Approach to Quality and Management Systems #

Vision Wide Tech is committed to delivering excellence through a robust quality management framework, underpinned by internationally recognized certifications and a culture of continuous improvement. Our approach integrates systematic processes, staff engagement, and advanced quality engineering to ensure that our products and services consistently meet and exceed client expectations.

Certifications and Standards #

We adhere to stringent international standards, holding the following certifications:

- ISO 9001:2015 Quality Management System (certified by TÜV NORD)

- ISO 14001:2015 Environmental Management System (certified by BUREAU VERITAS)

- ISO 9001:2008 Quality Management System (certified by TÜV NORD)

- ISO 14001:2004 Environmental Management System (certified by BUREAU VERITAS)

- Machinery Directive: 2006/42/EC

- Electrical Safety: EN60204-1:2006

- Low Voltage Directive: 2004/108/EC

- Electromagnetic Compatibility: 2004/108/EC (certified by Safenet, U.K.)

All certifications are validated by PMC (Taiwan) and Safenet (U.K.), ensuring compliance with CE requirements.

Total Quality Management (TQM) #

Total Quality Management (TQM) is central to our philosophy. This quality-focused management method aims for long-term success by prioritizing client satisfaction and benefiting all members of the organization and society. Full participation from all staff forms the foundation of our quality-driven culture.

Quality Control Circle (QCC) Initiatives #

By establishing Quality Control Circles (QCC), we foster continuous improvement to address practical operational needs. This includes:

- Element analysis

- Implementation planning

- Data collection

- Standard setting

- Post-analysis and precision improvement

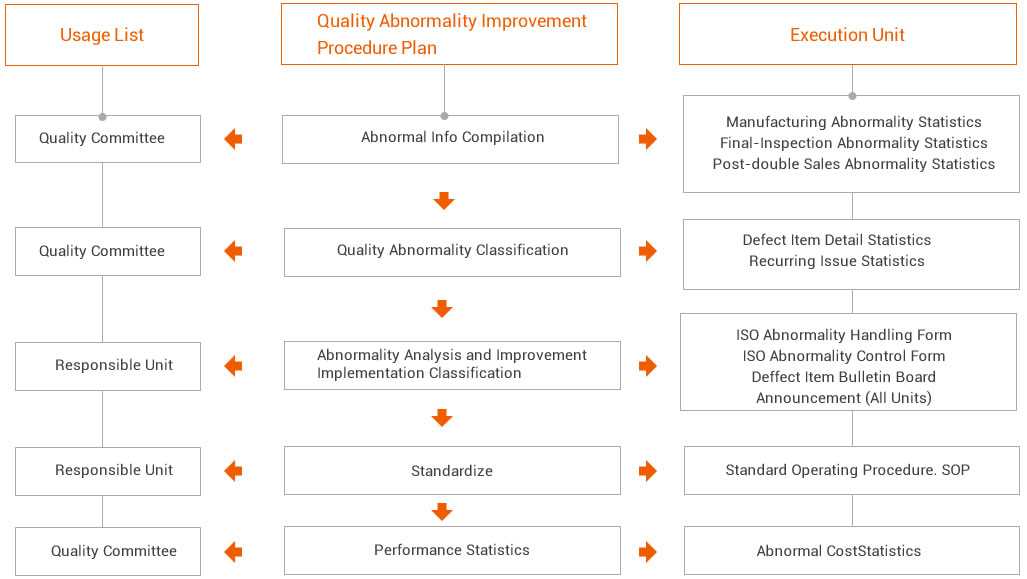

- Technical issue resolution

We utilize tools such as permutations, causal maps, histograms, stratification, correlation diagrams, control charts, and statistical analysis tables to identify root causes. Abnormalities from all departments are systematically compiled, tracked, and resolved.

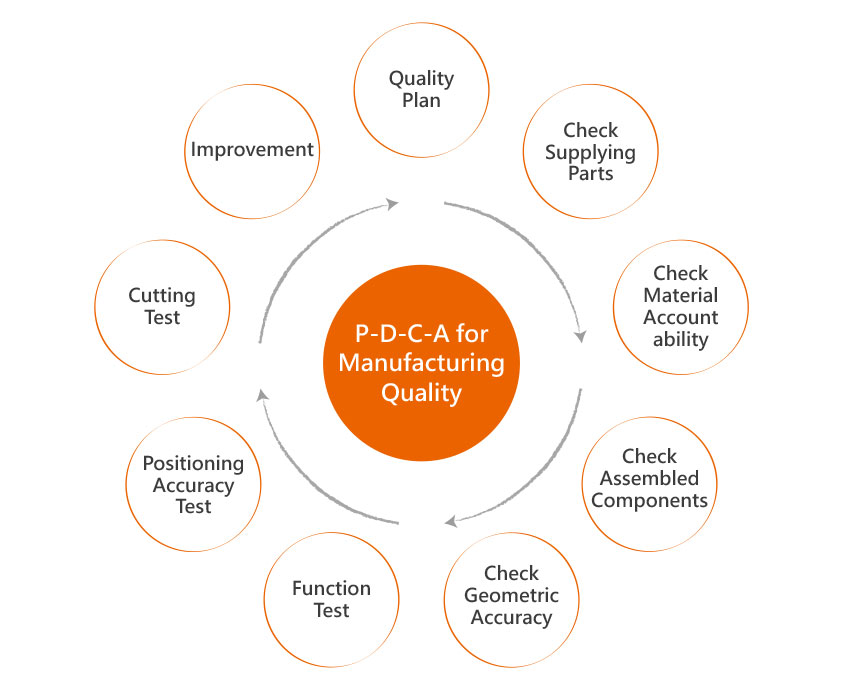

Quality Engineering Implementation #

Our commitment to quality engineering is reflected in the structured application of advanced methodologies and data-driven decision-making.

All-Staff Participation and Continuous Improvement #

To ensure comprehensive staff involvement and ongoing enhancement, we have implemented the 4S methodology (Sort, Set in Order, Shine, Standardize) since 2008, and have since advanced to 6S by adding Sustain and Security.

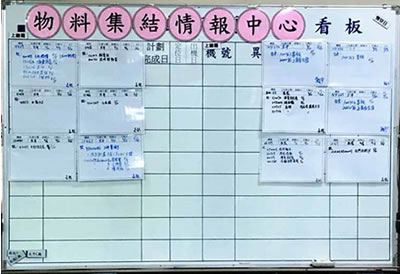

Visual Management #

We leverage visual management tools such as statistical graphs, billboards, images, color coding, signage, and numerical indicators to streamline daily operations and communication. This approach ensures transparency, real-time awareness, and highlights areas for improvement, making information accessible and actionable for all team members.

Our comprehensive implementation of the TQM system is a testament to our dedication to quality, ensuring that we consistently align with and fulfill our clients’ expectations.